Hydrophobically modified block-copolymer aggregates for turbulent drag reduction

Hydrophobically modified block-copolymer aggregates for turbulent drag reduction

Research questions:

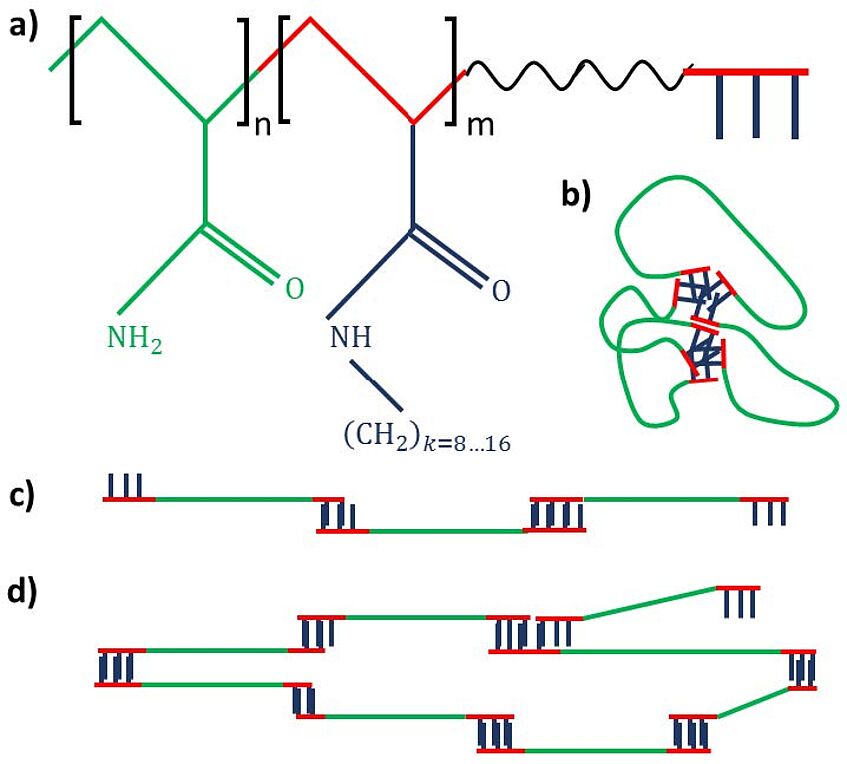

Small amounts (≥ 100 wppm) of high molecular weight polymers reduce drag in turbulent pipe flows (up to 80%) [1, 2]. Numerous models [3-6] exist for polymeric drag reduction but none does fully explain all experimental observations. Turbulent shear acting on polymers causes mechanical degradation of the polymers reducing their molecular weight and thus the drag reducing capability [1]. We will synthesise water soluble block-copolymers with hydrophobic blocks to self-assemble into aggregates in water and will tackle the following questions: Can we tailor the polymer architecture? What is the degradation behaviour of such polymers? Will these polymers recover after mechanical shear degradation? Can the association strength between the hydrophobic blocks be controlled? How does turbulent flow interact with these polymers? Will it be possible to control the morphology of polymer aggregates in solution? This will enable us to investigate the importance of polymer networks in turbulent drag reduction.

Hydrophobically modified blockcopolymer

assembly.

Methods:

We developed a procedure to synthesise hydrophobically modified PAAm copolymers [7]. The synthesis route will be optimised to introduce supermolecular motifs with controlled hydrophobic interactions and adjustable morphology of polymer aggregates. The polymers will be characterised by NMR and triple detection gel permeation chromatography. Structure and association behaviour in solution will be investigated by rheology and light scattering. Polymer shear flow interaction and drag reduction will be studied in controlled rheometer experiments and in our test facility, which allows for Reynolds numbers up to 106 and consists of a 7 m long test section with variable pipe diameters equipped with particle imaging velocimetry.

Time frame:

Months 1-36: polymer synthesis and optimisation of polymer architecture; months 9-39: polymer characterisation; months 16-42: polymer - fluid flow interaction experiments; months 43-48: writing of papers and thesis.

Participating DCAFM-faculty:

A. Bismarck (PI), C.Likos & S. Kantorvich (self-assembly and dynamics, viscoelastic behaviour)

[1] W. Brostow et al., J. Mat. Res. 22, 56 (2007); DOI: 10.1557/jmr.2007.0003

[2] A. Bismarck et al., Heat Exchanger Design Updates, 11, 25 (2004);

[3] J. L. Lumley, Annual Rev. Fluid Mech., 1, 367 (1969); DOI: 10.1146/annurev.fl.01.010169.002055

[4] G. Ryskin, PRL 59, 2059 (1987); DOI: 10.1103/PhysRevLett.59.2059

[5] M. Tabor and P.G. de Gennes, EPL 2, 519 (1986); DOI: 10.1209%2F0295-5075%2F2%2F7%2F005

[6] A. Yoshizawa, Phys. Fluids, 15, 3875 (2003); DOI: 0.1063/1.1623197 [7] E. Lam, PhD thesis, Imperial College, London (2012).